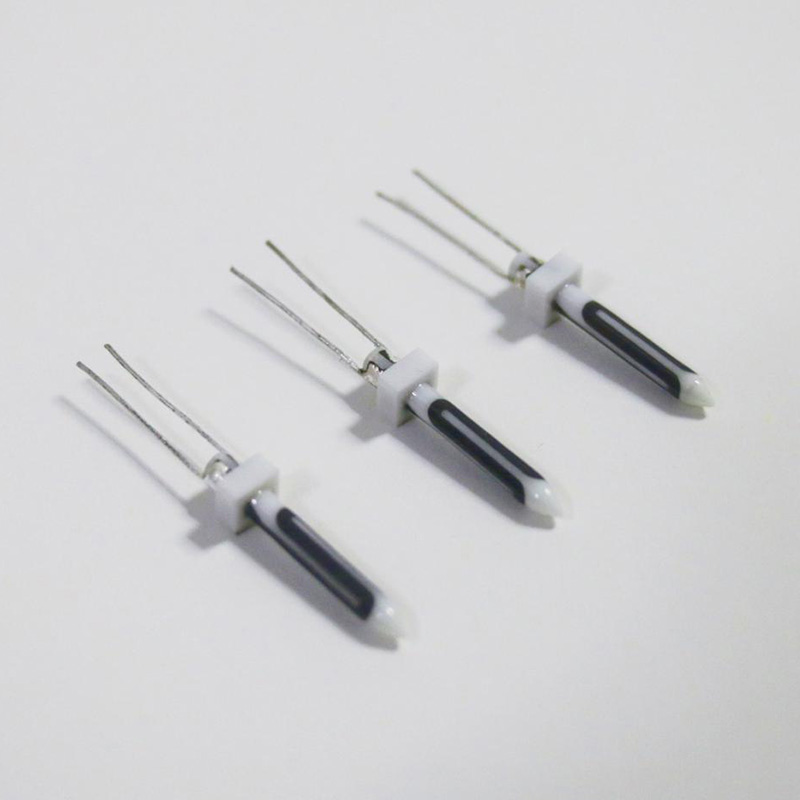

I-Zirconia Rod Ceramic Heating Element yombane we-DC isixhobo se-E-cigarette

Ukuqaliswa kwe-Keycore Ⅱ (HTCC ZCH) yobushushu obuphezulu be-zirconia

Ukunyuka kweqondo lokushisa ngokukhawuleza

Uyilo lwangaphakathi olunomngxuma

Izinto zeZironia

Electrode ubushushu obuphezulu bebrazing yesilivere

Amandla okugoba anokufikelela kwi-15KG. Kuphindwe kathathu incam ye-zirconia heater enkulu (ye-IQOS) kunye namaxesha angama-1.5 amakhulu kune-tip alumina heater.

Ukusetyenziswa kwamandla aphantsi, i-29% ephantsi kune-Keycore I

Ukufudumeza ngokukhawuleza, xa kuthelekiswa ne-alumina Keycore I, ikhawuleza imizuzwana eyi-7.5 ukuya kuthi ga kwi-350 ℃, ukufudumeza ngokukhawuleza kunyuke ngamaxesha ayi-1.7.

Ubushushu beFlange buphantsi, imizuzwana engama-30 kwi-350degrees, ubushushu beflange bungaphantsi kwe-100 ℃.

| Ububanzi | 2.15±0.1mm |

| Ubude | 19±0.2mm |

| Ukumelana nokufudumeza | (0.6-1.5)±0.1Ω |

| Ukufudumeza i-TCR | 1500±200ppm/℃ |

| Ukunyangwa kweSensom | (11-14.5)±0.1Ω |

| Uluvo lwe-TCR | 3500±150ppm/℃ |

| I-Lead Soldering imelana nobushushu | ≤100℃ |

| khokela amandla okuqina | (≥1kg) |

Iimeko zokuvavanya: i-voltage yokusebenza iya kwenza ubushushu bomhlaba wemveliso bufikelele kwi-350 degrees, kwaye emva koko uvavanye ubushushu be-flange emva kwe-30S yokuzinza.

Ukushisa kwe-flange ye-Keycore II (HTCC ZCH) iphantsi xa isebenza. Ubushushu be-flange emva kwemizuzwana ye-30 yokugcina ubushushu be-350 ℃ kumbane osebenzayo we-3.7v ayikho ngaphezu kwe-100 ℃, ngelixa i-Keycore I ijikeleze i-210 ℃ phantsi kweemeko ezifanayo.

Izifudumezi zeCeramic zinezi mpawu zilandelayo:

Uzinzo oluphezulu lweqondo lokushisa: Izinto ze-Ceramic zinozinzo oluphezulu lweqondo lokushisa kwaye lunokugcina ukusebenza okuzinzileyo kwiindawo eziphakamileyo zeqondo lokushisa, ngoko ke zifanelekile kwiimeko zokushisa eziphezulu.

Ukumelana ne-Corrosion: Izixhobo ze-ceramic zinokumelana okuqinileyo kwe-corrosion, zinokusebenza kumajelo athile e-corrosion, kwaye zilungele iimfuno zokufudumeza kwiindawo ezikhethekileyo.

Ukusebenza kwe-insulation: Izinto ze-Ceramic zineempawu ezintle zokugquma, ezinokuthintela ngokufanelekileyo ukuvuza kwangoku kunye nokuphucula ukusebenza kokhuseleko lokufudumala.

Ukufudumeza okufanayo: Izifudumezi zeCeramic zinokufikelela kwisiphumo sokufudumeza esifanayo, ukuphepha ukufudumeza kwendawo okanye ukupholisa ngaphantsi, kwaye zifanelekile kwiimeko ezifuna ukufudumeza okuphezulu.

Ukonga amandla kunye nokukhuselwa kwendalo: Izifudumezi zeCeramic zihlala zisebenza ngamandla kwaye zinokuguqula amandla ombane abe ngamandla obushushu ngobuchule obuphezulu, ngaloo ndlela kuncitshiswa ukusetyenziswa kwamandla kunye nokuhlangabezana neemfuno zokonga umbane kunye nokhuseleko lokusingqongileyo.

Ubomi obude: Ngenxa yokuba izinto ze-ceramic zinokuxhathisa okulungileyo kunye nokuzinza, izifudumezi ze-ceramic zihlala ziphila ixesha elide.

Ngokubanzi, izifudumezi ze-ceramic zineempawu zokuzinza kobushushu obuphezulu, ukuxhathisa kwe-corrosion, ukufudumeza, ukufudumeza okufanayo, ukonga amandla kunye nokukhuselwa kwendalo, kunye nobomi obude, kwaye zifanelekile kwiindidi ezahlukeneyo zemizi-mveliso kunye nekhaya.