Isisombululo se-Ceramic coil vape

Ubuchwephesha be-Silicore yiplatifomu ye-atomization esekelwe ekufumaneni ibhalansi phakathi kwamandla, ukushisa kunye nokuhamba.

Indlela yomoya:

Umoya womoya uchaphazela ukuvuza kweoli, i-condensate, njl. indlela yomoya ayinaso isithinteli sokungenisa umoya. Ngokusetyenziswa kwe-e-liquid, umoya kwindawo yokugcina i-oyile iyanda, yenza umehluko woxinzelelo, omele ukuvuza ioli.

Indlela ye-oyile:

Iipaseji zeoyile ezenziwe kakubi ziya kukhokelela ekutshiseni kunye nokwakhiwa kwekhabhoni. Ukuba indlela yeoyile ivalwe ngamaqamza omoya, kwaneyona nto ikhawulezayo yeatomizer iya kuba yikhabhoni.

Ukufezekisa incasa egqithisileyo, ubushushu obufanelekileyo be-atomization yeoli yomsi iyimfuneko. Ukuthelekisa iipropati ze-thermodynamic kunye namandla e-ceramic atomizer cores ngundoqo.

Uhlobo lwe-E-liquid:

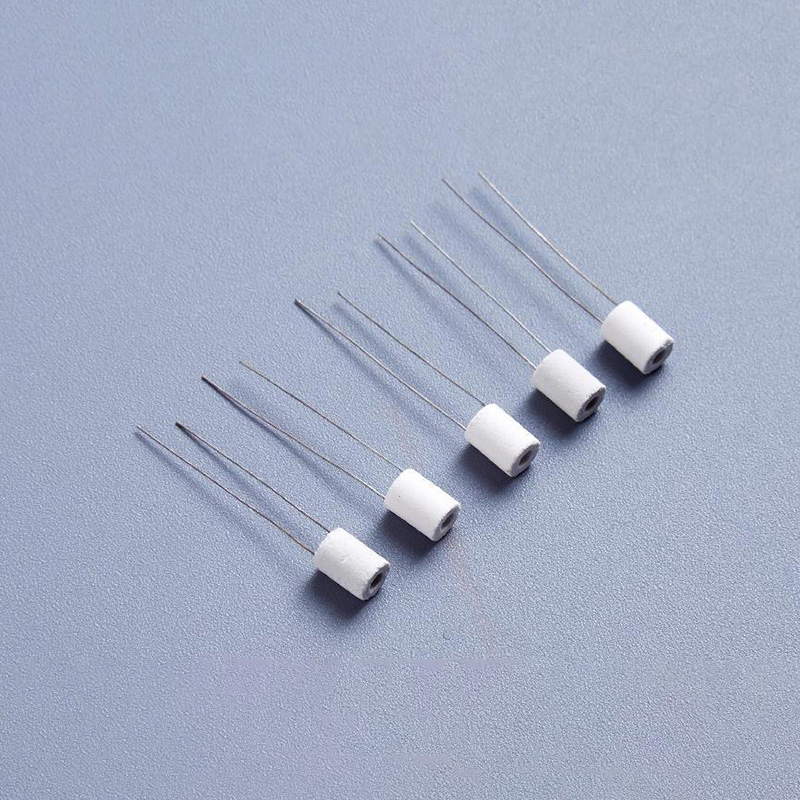

Icuba elilahlwayo, elimanzi kunye ne-e-sweet ephezulu kufuneka ikhethe icoil yeceramic yeenwele ezithe nkqo, kuba indlela yomoya imfutshane.

Ukutshintsha ibhulethi kunye ne-e-liquid elahlayo kunye nentsha, kufuneka ukhethe ikhoyili yeceramic ecaba.

Amandla:

<7W khetha ifilim engqindilili ye-ceramic ikhoyili, ethi ngokugqabhuka ngamandla, ifuna kuphela amandla aphantsi ukufikelela kubushushu obufanelekileyo be-atomization;

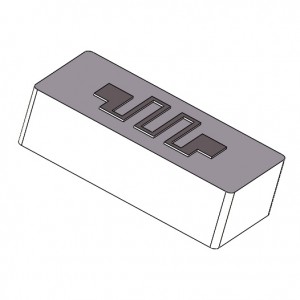

> I-7.5W khetha i-coil ye-ceramic ye-SMD, efuna amandla aphezulu ukufezekisa ubushushu obufunekayo be-atomization.

Viscosity yolwelo lwecuba:

I-viscosity ye-e-liquid ichaphazela ngokuthe ngqo ukushisa kwe-atomization. Emva kokumisela i-viscosity ye-e-liquid, i-coil ye-ceramic iyona nto ikhethekileyo. Isantya sokuqhuba kwe-oyile sisantya sokuqhuba kwe-oyile esifunekayo ukufikelela kubushushu obufanelekileyo be-atomization. Ayikhawulezi kakhulu, ayicothi kakhulu.